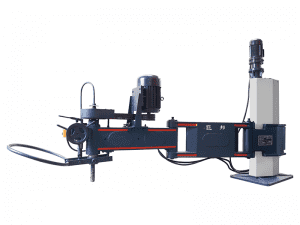

Stone Edge Grinding Machine

The grinding wheel of this machine adopts water grinding disc and is equipped with snail buckle joint. According to the different size and thickness of the stone, the right-angle bottom edge of various flat stones can be ground. The thickened straight edge is bright, the right-angle bottom edge is 45° chamfered, the straight edge is formed, and the begonia angle is cut back (first and second The motor can be equipped with a saw blade, the back cutting and bevel polishing can be completed at one time), and the polishing (rough grinding, fine grinding, polishing) processes are completed at one time, and the brightness after processing is higher than the brightness of the board surface.Advanced and reasonable structure, high accuracy, fast efficiency, convenient operation and simple maintenance. In the grinding process, the feeding speed and the amount of processing can be adjusted, and the maximum processing is 5m/min. The normal use of the machine is equivalent to the workload of 15 people in stone processing, and the process defects caused by manual processing are eliminated.

| Appellation | Unit | SEG11-164 | SEG8-125 |

| Min.processing width | mm | 80 | 80 |

| processing thickness | mm | 10-80 | 10-80 |

| Belt advanced speed | m/min | 0.8-5 | 0.8-5 |

| Number of grinding head(Optional) | pcs | 11 | 8 |

| Total power | kW | 33 | 36 |

| Power of main motor | kW | 3/4.5/5.5 | 3/4.5/5.5 |

| Dimension(LxWxH) | mm | 7500x1000X2000 | 7500X1100X2000 |

| Weight | kg | 3200 | 3300 |

Packing & Loading

All products have to pass strict inspection before leaving the factory, nude with plastic film and wire fixing.

After-sales service:

Thoughtful and efficient after-sales service, provide support and protection for your benefit

1. According to the contract, guide equipment installation, commissioning for customers on schedule.

2. On-site training, guide the customer about the product specification operation and technical use

3. Responsible for receiving and handling customer's suggestions and complaints about product quality and service quality

4. In warranty period, we will do the tracking and inspection unscheduled to implement our service with dynamic management.

5. If there is something problem with the machine during the warranty period, we will send someone to repair it for free

6. The customer can enjoy life-long after-sales service after the warranty period.

7. Responsible for training service personnel regularly, continuously improve the overall quality of service personnel

8. We provide customers with equipment failure maintenance personnel, business consulting, customer complaints and other recommendations the whole day.

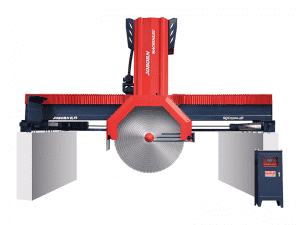

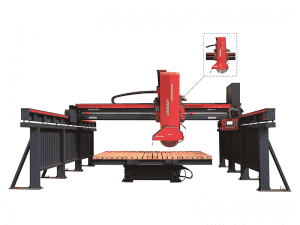

Products Recommended

Professional technical engineer dedicated to guide you

According to your actual needs, choose the most reasonable overall design and planning procedures